0086-755 2330 1799 martin@furuihua.net

A CNC milling machine can also be used as a CNC engraving machine. But CNC engraving will have a requirement to the spindle speed of the mill, due to the small-sized engraving tools and soft materials need a higher spindle speed. CNC milling engraving can be performed on stainless steel, mild steel, aluminum, brass, wood, plastics, and more materials.

A CNC Engraving Machine is the perfect tool for creating intricate designs with precision. These machines can be used to engrave on a variety of materials such as metal, wood, plastic, and even glass. With the ability to work on multiple axes, CNC engraving machines can create stunning designs that would be impossible to achieve by hand. CNC engraving machines can be used in a variety of industries, including jewelry, advertising, and even architecture. These machines allow for precise control over the depth and detail of the engraving, resulting in high-quality and consistent results. The advanced technology of these machines also allows for faster production times, reducing the need for manual labor.

Mineral Casting, sometimes referred to as granite composite, polymer-bonded mineral casting, artificial granite (AG) or epoxy granite, is a construction of material that is made of epoxy resin combining materials such as cement, granite minerals, and other mineral particles. During the mineral casting process, materials used for strengthening the construction such as reinforcing fibers or nanoparticles are added.

The materials that are made from a mineral casting process are used to build machine beds, components as well as high precision machine tools. To this end, the application of these materials can be seen in multiple industries such as aviation, aerospace, automobile, energy, general manufacturing, and engineering where precision is of major concern.

Besides the construction of synthetic materials, mineral casting as a metalworking process manufactures the iron-carbon alloys which contain a higher percentage of carbon in composition compared to a conventional iron casting process and therefore the casting temperature is lower than the traditional iron casting process because the material has a relatively lower melting temperature.

Mineral casting is a process of material construction that combines a wide range of ingredients to produce the end material. The two primary components of mineral casting are the specially selected minerals and the binding agents. The minerals that are added to the process are selected based on the requirements of the end material. Different types of minerals bring about different properties; with the ingredients combined, the end material is able to possess the characteristics of the ingredients it contains.

A binding agent refers to the substance or material used to form several materials into a cohesive whole. In other words, the binding agent in a material construction process serves as the medium that pulls the selected ingredients together to form a third material. The substances used as a binding agent include clay, bitumen, cement, lime, and other cement-based materials such as gypsum cement and magnesium cement, etc. The material used as the binding agent in a mineral casting process is usually epoxy resin.

Epoxy is a type of plastic that is made by the reaction of multiple chemical compounds. Epoxy resins are used in a wide range of industrial applications for they have excellent toughness as well as strong adhesion and chemical resistance. Because of these specialized properties, epoxy resins are used primarily in building and construction applications as adhesives to combine materials.

Epoxy resins are known as structural or engineering adhesive because they are used heavily in making construction materials such as walls, roofs, and other building materials where strong bonds to a variety of substrates are required. As technology advances, epoxy resins are used not only as a binder for construction materials but also as the binding agent in the material industry to construct high-quality materials for industrial use.

Mineral casting can be used for the production of materials for modeling, lightweight construction, bonding, and protection of machinery. The process for complex composite parts production is precise and delicate so that the end products can meet the requirements of the specific applications. Depending on the materials that are involved in a mineral casting process, the end products are constructed and equipped with the desired properties and characteristics for their job.

Mineral casting is able to secure the geometric position of the individual machine elements by means of absorbing the static, dynamic, thermal, and even acoustic forces. It can also be highly media-resistant to cutting oils and coolants. The force damping capability and chemical resistance of mineral casting make material fatigue and corrosion less of a concern to the machinery parts. Having these features, mineral castings are an ideal material for manufacturing molds, gauges, and fixtures.

In addition to the characteristics a mineral casting can possess granted by the minerals it contains, the casting environment also offers some advantages to it. The low casting temperatures combined with innovative precision and bonding technologies produce precise machine components with high functionality and an excellent level of integration.

Machine tools

Electronics manufacturing

Laser applications

Solar module production

Woodworking and textile machines

Measuring, testing, and inspection technology

Machinery used in energy technology

Special machinery

|

Features |

Unit |

Comparisons |

||||

|

Steel |

Cast Iron |

Marble |

Mineral Casting |

Comment |

||

|

Damping Factor |

|

0.002 |

0.003 |

|

0.02~0.035 |

Good Vibration Absorption |

|

Compressive Strength |

N/mm2 |

250~1200 |

600~1000 |

257.1 |

140~165 |

Bad |

|

Bending Strength |

N/mm2 |

150~600 |

100~300 |

36.7 |

15~55 |

Bad |

|

Tensile Strength |

N/mm2 |

400~1600 |

150~380 |

7-20 |

10~45 |

Bad |

|

Coefficient of Thermal Expansion |

10-6/k |

12 |

9 |

5.3-8.7 |

9~19 |

approximate |

|

Thermal Conductivity |

W/mk |

50 |

50 |

1.95 |

1~3 |

Good |

|

Specific Heat Capacity |

Kj/(kgK) |

0.49 |

0.45 |

0.70 |

0.7~1.25 |

Good |

|

Elastic Modulus |

kN/mm2 |

210 |

80~120 |

10-90 |

30~52 |

Deformation resistant |

|

Density |

g/cm2 |

7.85 |

7.15 |

3.07 |

2.4~2.6 |

Low |

|

Poisson Ratio |

|

0.3 |

0.2~0.3 |

0.2-0.3 |

0.25~0.35 |

approximate |

|

Cost |

|

high |

Very high |

high |

Low |

Low |

|

Item |

|

FRH |

|

|

Material cost |

5 USD/KG |

2.5 USD/KG |

|

|

Development cost |

Design cost |

60,000 USD/PC |

5,000~10,000 USD/PC |

|

Moulding & |

30,000~60,000 USD/PC |

5,000 USD/PC |

|

|

Lead time |

|

3~6 months |

1~3 months |

|

Item |

SCHNEEBERGER | RAMPF | FRH | Comparison |

|

Density 密度(g/cm³) |

2.3 |

2.3-2.4 |

2.35 |

approximate |

|

Modulus of elasticity |

38-45 |

30-45 |

43 |

Good |

|

Compressive strength |

110 |

130-160 |

135 |

Good |

|

Tensile strength |

13 |

13-15 |

15 |

Good |

|

Poisson's ratio |

0.2 |

0.28-0.3 |

0.22 |

approximate |

|

Therm expansion coefficient |

16 |

15-19.5 |

15 |

Good |

|

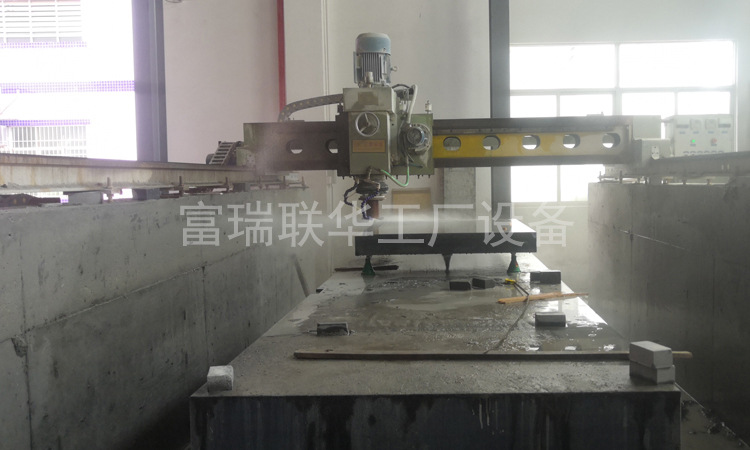

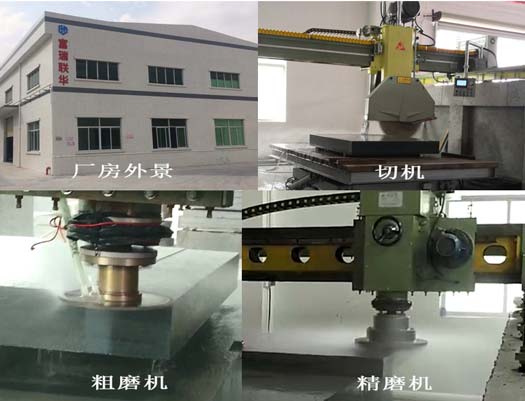

Production Equipment |

|||

|

No. |

Name |

Specs. |

Qty. (set) |

|

1 |

Gantry crane |

30 ton |

1 |

|

2 |

Gantry crane |

|

2 |

|

3 |

Gantry crane |

5 ton |

2 |

|

4 |

Automatic cutting machine |

1mm |

3 |

|

5 |

Polishing machine |

φ300-φ6000 mm |

5 |

|

6 |

Improved leveling machine |

1mm |

5 |

|

7 |

Grinding machine |

0.2mm |

5 |

|

8 |

Drilling machine |

0.05mm |

5 |

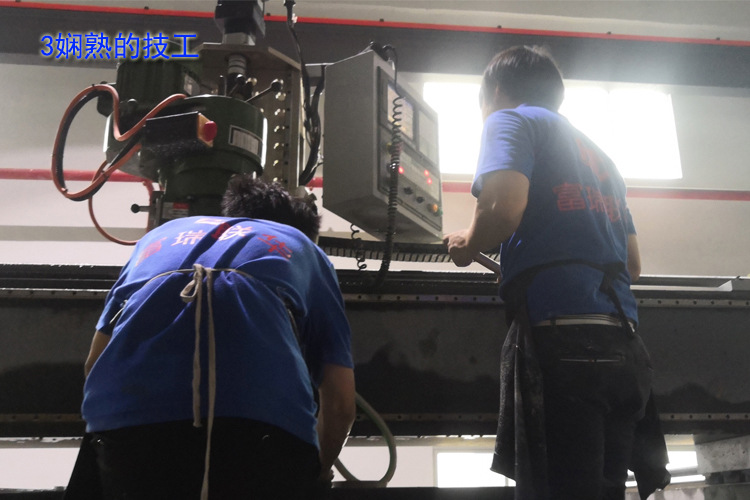

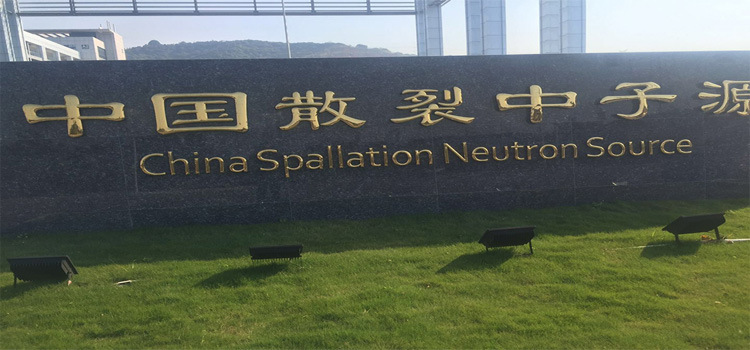

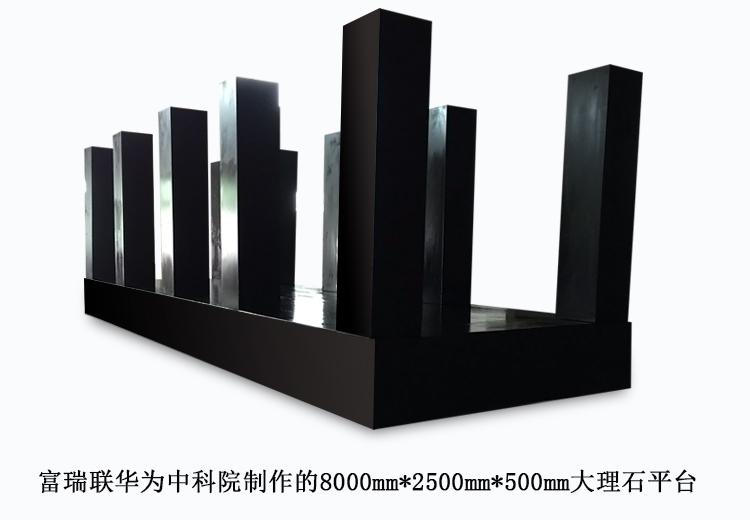

FRH uses the top-quality black granite in the world to make the precision granite surtace plate with stand.

Our superior black granite has the extremely low coefficient of water absorption, so it can minimize the possibilty of your precision gages rusting while seting on the plates. This black granite creates little glare resulting in less eye strain for individual using the plates.

We have chosen our superior black granite with the specific intent of keeping thermal expansion to a minimum.

Custom requirements

The custom option is available.

UFRH can make the granite plate according to your specific requirements, we also can help you imporve the drawing for your project, including custom sizes, thicknesses. If you need to add holes, counterbores, threaded or solid stainless steel inserts, dovetail slots and t-slots to vour surface plate, we can do that as well.

All our granite products are processed and tested under the strict standard before delivery, the tolerance of flatness is 1.6 um.

Skype: 008618928353328

Phone: 0086-189 2835 3328

Tel: 0086-755 2330 1799

Email: martin@furuihua.net

Add: 2nd. Floor, Building 17, #16 Wunipeng Rd., 3rd. Industrial Park, Wanfeng Community, Xinqiao Street, Baoan Dist., Shenzhen 518104